Dera Mes Manufacturing Execution System

DERA MES

Dera MES is a manufacturing execution and automation system developed by Dera Technology based on real-time monitoring of the production site. It increases efficiency, reduces costs, and provides competitive advantages through automated production floor data collection, online monitoring, analysis, and information sharing.

DERA MES Solutions

System Management

It is the module that contains the basic definitions for the operation of the system, such as workplace, personnel, stop, scrap, key users, checklist.

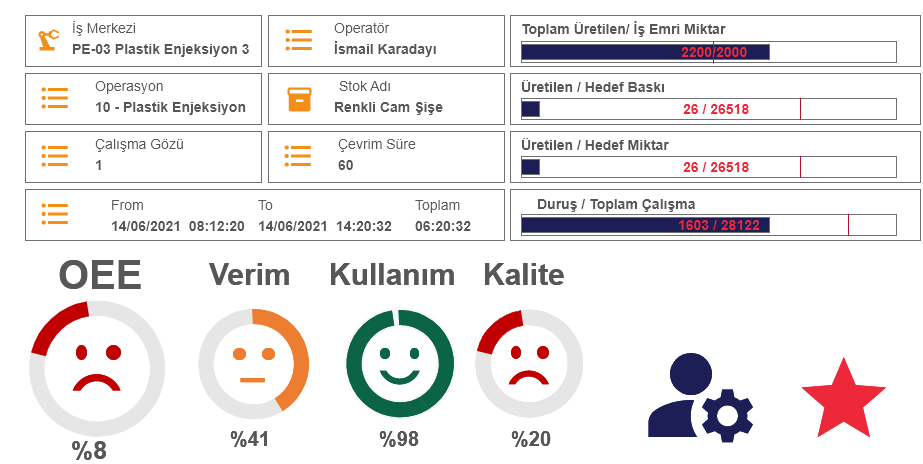

Shop Floor Control

It enables real-time production monitoring from field of workstations.

Project Planning

It allows you to make changes to production data by displaying it as a list in real time.

Shop Floor Monitoring

It allows operators to monitor production records, schedules and production performance in real time.

Analysis and Reporting

It allows you to get ready-made reports according to the date ranges and parameters you want. In this way, you can carry out the necessary improvement studies and updating processes.

ERP Integration

It transfers the necessary data such as the work order list from the existing ERP system to the MES.

Maintenance Management

Breakedown tracking, work order opening and email notification, equipment maintenance tracking, scheduled maintenance activity input and machine programming integration, scheduled maintenance activity instruction tracking, automated maintenance work orders, MTBF and MTBR report tracking, etc. includes features.

Quality Management

Quality defects can be analyzed, examined in categories, and defect logs can be created. Root cause analyzes of similar quality defects can be performed and positive effects on the OEE of production are given.

Inventory Management

It provides inventory management integrated with MRP, sales, purchasing, project and production modules. Inventory management is tracked in real time from purchasing to the end of production.

Document Management

During the execution of the work order, personnel can also access the related technical drawings, quality, environmental, control and project documents through the operator screens. 2D and 3D files can be also displayed.

What does Dera MES do?

Real Time Work Tracking

You can monitor the production, efficiency and failure data of workstations in real time.

Storage of Data

By turning the reliable data you collect in the field, in real time and automatically, into information, you can leverage it at every level, develop actions, plan, and use it in your decision support systems.

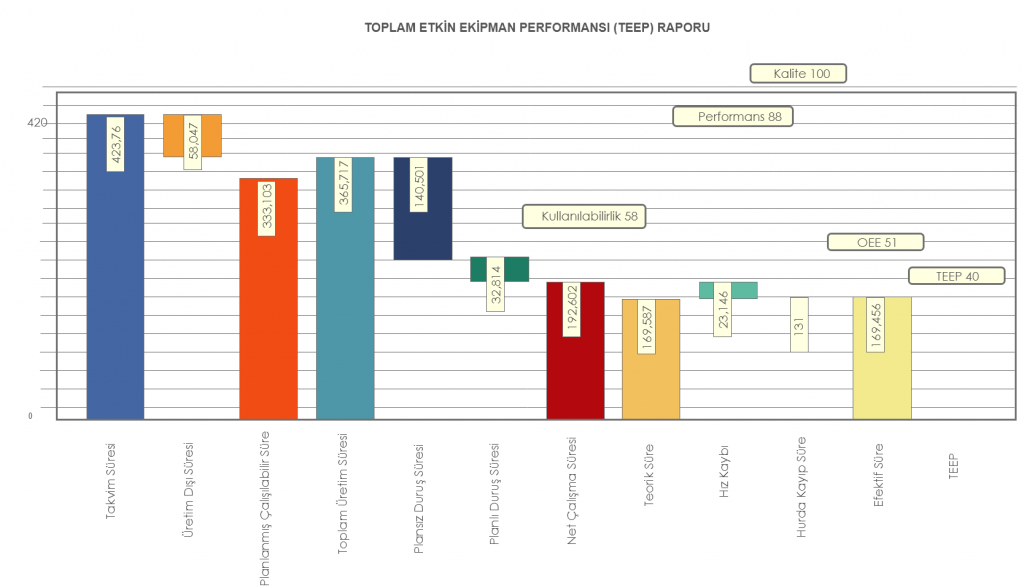

Analysis and Reporting

You can generate analysis reports by calculating overall equipment efficiency, capacity utilization, production output, quality, actual working time, PPM, MTBF- MTBM, UCL-LCL -Cp data with data collected from production.

Lean Production

By analyzing data such as downtime, reason for downtime, scrap quantity, reason for scrap, you can identify bottlenecks in your business and take action.In this way, you create a lean production line by minimizing non-value-added activities.

Benefits of DERA MES

Increase ın effıcıency

Minimum 30% increase in production efficiency

ıncrease ın qualıty rate

Decreasing scrap losses with increasing quality rate

ıncrease ın OEE

Increase overall equipment efficiency (OEE) through increased production efficiency, machine utilization and quality

Decrese ın breakdown

Prevention of future failures with root cause analysis as a result of reporting machine breakdowns

AUTOMATIC AND EFFORTLESS REPORTING

Repetitive processes are reduced and a paperless production environment is created.

decrease ın cost

Reduce costs by reducing scrap and downtime

Contact Us

Get Support

Manage your production line with real-time data. Reduce your costs by improving your production performance. Contact us to plan factory discover visit.